hdd - Did you get what you paid for? coating still there?

DCVG & CP CIPS. ACCA & ACVG. pipeline inspection.

ScanTegrity™ ACCA and ACVG OnePass™

ScanTegrity™ ACCA and ACVG OnePass™

ScanTegrity™ ACCA and ACVG OnePass™

The ScanTegrity Buried Pipe pipeline inspection Corrosion Scanning ACCA + ACVG System is a two-part system comprising a Generator and a Detector. The Generator is connected to a buried pipe at a CP test post, flange bolt, valve, or other appurtenance, and to a remote earth spike. The generator injects a controlled, 600 milliamp, AC current, onto the pipeline, which decreases with distance, as the current leaks through the coating. This current produces a magnetic field that is received by the Detector.

The Pipeline External Corrosion Direct Assessment Detector measures the characteristics of the magnetic field, giving the following information:

- Depth (if overhead)

- Cover (the depth to the top of the pipeline if the diameter is entered)

- Distance to the pipeline (if not overhead – up to 10m away)

- Angle (the angle of the pipeline to the Detector)

- Current (the current remaining on the pipeline below the detector)

The current value and distance between survey points is used to calculate Attenuation, in milli-Bels/meter (mB/m which is one-hundredth of a deciBel, dB). The attenuation is an indication of the coating quality. Higher values indicate degraded coating.

Pipeline GPS GIS Mapping

ScanTegrity™ ACCA and ACVG OnePass™

ScanTegrity™ ACCA and ACVG OnePass™

The built-in GPS can track 12 satellites and can acquire lock within 45 seconds from a cold start.

With an accuracy of 2m, the GPS coordinates are used to calculate the linear distance between two survey points.

For sub-centimeter accuracy to one inch in 3D, with KML output file, an optional external Trimble unit can be plugged into ScanTegrity. External pipeline inspection GPS positioning data is saved automatically with the survey readings.

The reports issued include coordinates for every data read captured, within a KML file, which is the Google Earth™ file format.

ScanTegrity Surveys Include:

►NACE RP-0502: Pipeline External Corrosion Direct Assessment Methodology using DCVG & CP CIPS

► NACE TR41013: External Corrosion, Assessment, and Control of Buried Piping Systems in Nuclear Power Plants

►NACE TM0109: Aboveground Survey Techniques for the Evaluation of Underground Pipeline Coating Condition

►NACE TM0102: Measurement of Protective Coating Electrical Conductance on Underground Pipelines

Pipeline Reporting Tools

ScanTegrity™ ACCA and ACVG OnePass™

Pipeline Conductance Report

After a pipeline inspection survey is complete, the ScanTegrity™ Pipeline Coating Scanning detector can be connected to a computer running ReportTegrity™ DCAPP.

Once downloaded, ReportTegrity will display all the survey data in graphical and tabular form. Reports can be printed with graphs or without.

Pipeline External Corrosion Direct Assessment Reporting is customizable to modify the data in many ways:

- Attach Comments to each survey point

- Add/amend pipeline details

- Edit Survey Details

- Ignore rogue survey points

- Auto Analyze Survey Data

- Fill in missing GPS points

- Fix bad GPS point

- Filter Survey Data (by distance or attenuation)

- Change coating type

- Change soil resistivity

- Set custom coating/Relative Permittivity

- Change survey direction

Pipeline Conductance Report

Pipeline Conductance Report

Pipeline Conductance Report

ScanTegrity™ Pipeline Inspection Coating Scanning conforms to the “AC Current attenuation survey” as specified in NACE RP0502.

The calculations use the following:

- Ground resistivity

- Coating type (FBE, coal-tar etc) or the electrical characteristics of coating

- Pipeline diameter

- Pipeline wall thickness

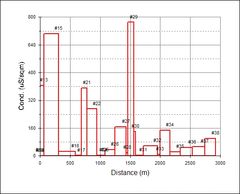

Without entering the above data only a (very) crude estimation of conductance can be given. NACE values of conductance, are as follows:

Less than 100 μS/m2 Excellent coating

100uS to 500 μS/m2 Good to fair coating

500uS to 2000 μS/ m2 Fair to bad coating

Above 2000 μS/ m2 Bad to no coating

The graph above shows the relationship to Attenuation for Bitumen coating. Pipeline External Corrosion Direct Assessment can use either DCVG & CP CIPS or ACCA & ACVG.

Microsiemens Conductance

Pipeline Conductance Report

Microsiemens Conductance

Pipeline Inspection Conductance, in μS (microsiemens) per square metre, is an absolute value of the ability of the coating to pass current. Microsiemensis the reciprocal of resistance and is used in preference to ohms (resistance) as specified in NACE TM0102-02. Pipeline External Corrosion Direct Assessment Alternating Current-Current Attenuation (ACCA) will display μS/m², μS/m or Ω/m² if required.

Coating Fault Detection

Pipeline Conductance Report

Microsiemens Conductance

In regular use in over 49 countries by the world’s petroleum and gas industries, the ACCA Pipeline Coating Scanning systems evaluate the coating condition of buried transmission pipelines.

ScanTegrity pipeline inspection gives unrivaled measurements of depth of cover, coating quality and GPS position without physical contact with the pipeline. The non-contact measurement allows surveying over concrete, roads and water with equal accuracy, Pipeline External Corrosion Direct Assessment DCVG & CP CIPS is also available.

HDD integrity validation - ScanTegrity™ attenuation survey Photo Gallery

Under River Approach - HDD Coating Cathodic Protection Integrity Scan - ScanTegrity™ HDD Coating Scan

how do you know your cathodic protection remains after hdd?

Are You Meeting, or Exceeding, U.S. Code of Federal Regulations (CFR) Title 49, Parts 192 and 195?

ScanTegrity™ pipeline inspection attenuation survey verifies whether you had a coating failure on your HDD. Did you receive what you paid for with your Horizontal Directional Drilling pipeline installation? Pipeline External Corrosion Direct Assessment using ACCA is the only way to know whether your pipe was scraped bare during horizontal directional drilling.

192.461, External corrosion control: Protective coating.

• (c) Each external protective coating must be inspected just prior to lowering the pipe into the ditch and backfilling, and any damage detrimental to effective corrosion control must be repaired.

• (d) Each external protective coating must be protected from damage resulting from adverse ditch conditions or damage from supporting blocks.

• (e) If coated pipe is installed by boring, driving, or other similar method, precautions must be taken to minimize damage to the coating during installation.”

Pipeline External Corrosion Direct Assessment using ACCA is the only way to know whether your coating was lost.

HDD installations? Precautions must be taken to minimize damage to the coating during installation.

What pipeline inspection precautions are you taking to minimize damage? One precaution is to inspect, with ScanTegrity™ attenuation survey, every HDD-installed pipe you put in the ground, the day the pipeline is pulled.

ScanTegrity buried pipe surveillance finds your holidays, so you don’t miss yours.™

The ScanTegrity Current Attenuation methodology has been recognized by NACE as an approved method of coating evaluation for transmission pipelines under NACE RP0502 and NACE TM0102. With the included DCAPP program, detailed reports can be generated including pipeline position maps and coating conductance values. ScanTegrity Tool purchase comes with free software and firmware updates, ensuring that operators benefit from improvements.

scantegrity™ Downloads

ScanTegrity™ Pipeline Inspection External Corrosion Direct Assessment (ECDA) Downloads

ScanTegrity™ - White Paper Eagle Ford - Alternating Current-Current Attenuation Survey (pdf)

DownloadCopyright © 2020 Tegrity.LLC - All Rights Reserved. +1-312-767-7351